ABOUT CAD JEWELRY DESIGN

CAD (Computer Aided Design) is the CAD jewelry design process of using 2D information (your pictures or drawings) and making them into a 3D computer file. Once a 3D file is finished the design can be viewed at any angle or zoom level, complete stone sizes, counts and weights are known, precise metal weights in any metal is known, alterations can be made quickly, all without wasting time or money on needless production. There is really no comparison to the old method which often took weeks just to look at one rough hand carved wax sample. With the old jewelry design process if you needed just one revision, it could take another several weeks for a busy hand jewelry wax carver to return to the job.

Click the play button below to watch a walk through of the complete cad jewelry design process in less than 6 minutes!!

Click the play button below to watch a walk through of the complete cad jewelry design process in less than 6 minutes!!

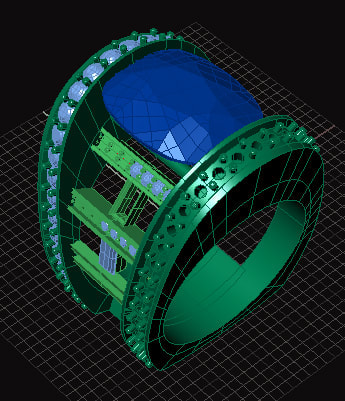

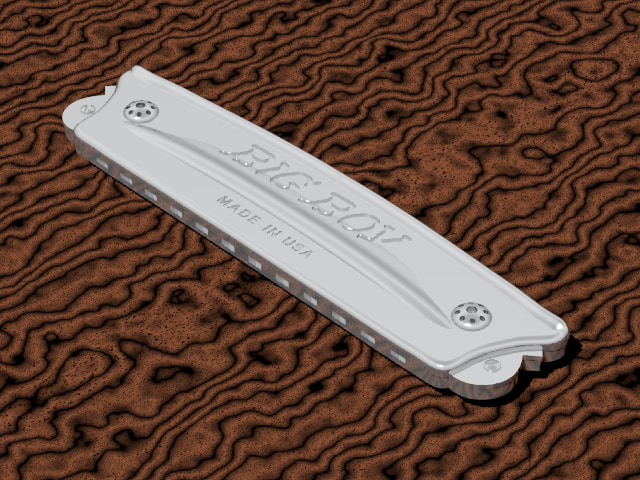

The first two pictures below show an actual CAD Jewelry Design job. The new jewelry design was based on an old picture but the customer wanted changes to the size/type of center stone, the thickness of the ring, size of side diamonds and finger size. The customer received 4 views for their approval, then photo realistic renderings before the final approval was given.

The following set of 14 pictures show actual CAD Jewelry Design photo realistic pictures of completed jewelry designs. These examples show the diversity of images with and without gemstones and with different types of backgrounds. Some production houses prefer small prongs be built into the model, while others prefer us to supply a stone layout with pilot holes so the setter can micro pave set with precision. Whichever setting style you prefer we will deliver.

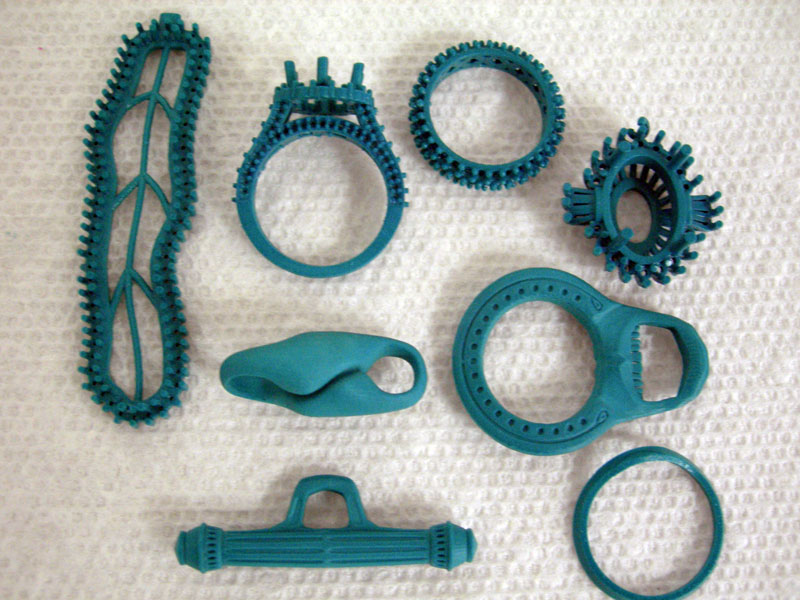

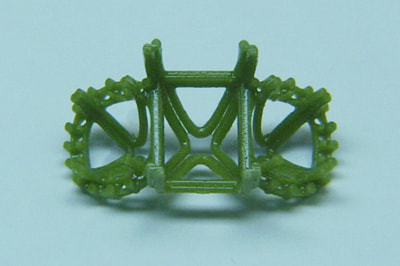

When final approval is received we generate the STL file. The STL file is then sent to a high resolution rapid prototyping machine which makes the master models. Play the video above to see a high resolution wax printer in action. Below are 3 pictures of high resolution wax jewelry models suitable for direct casting. These are wax and require zero changes to the regular burnout process. We prefer wax jewelry models as they have the best surface finish and cast just like a hand carved wax. Resin jewelry models can also be printed from the same STL file. Resin has the advantage of being much more durable however resin jewelry models have a lower quality surface finish. Another issue with resin jewelry models is they often need different burnout procedures, different investment powder (used in the casting flask). Resin jewelry models do have important uses but with some geometries resin models will have casting issues like porosity from the resin leaving ash residue in the flask during casting.

Below we have pictures which show the high resolution wax jewelry models given to the caster. The caster builds a "tree" of wax models (below left), puts the "tree" into a flask (below right), pours investment which hardens around the wax models... then the wax is burned out. Burning out leaves empty voids in the size and shape of the wax models.

Below left picture shows the wax tree, after the investment is poured in and dries into a hard porous material encasing the wax models. Casting is the process of pulling molten metal by using centrifugal force or vacuum into those cavities. Regardless of the design, casting can be done with the metal of your choice, different color golds, platinum, palladium, silver, alloy, etc. The below right picture shows the metal "tree" after casting, it has already been taken out of the flask and has the hardened investment removed. At this point, the casting, can either go to pre-finishing, where numerous molds can be made for jewelry production or it can go straight into setting and finishing if no molds are wanted.

If you are looking for a top rated GIA diamond buyer PLEASE CLICK HERE.

If you are looking for a top rated large diamonds buyer PLEASE CLICK HERE.

If you are looking for a top rated large diamonds buyer PLEASE CLICK HERE.

CAD JEWELRY DESIGN

Many people are now lowering costs and increasing sales by being able to bring jewelry designs to the market faster. With our Cad Jewelry Design files you can reduce gemstone breakage with more accurate castings, make rapid design changes and reduce in-house development costs. When creating a line it is more effective to be able to borrow design elements from one CAD jewelry design and bring them straight into the next design.

Are you ready to begin! Simply click here to contact us

I will make sure you will be completely satisfied with your 3-D CAD jewelry design file or custom designed finished jewelry.

Many people are now lowering costs and increasing sales by being able to bring jewelry designs to the market faster. With our Cad Jewelry Design files you can reduce gemstone breakage with more accurate castings, make rapid design changes and reduce in-house development costs. When creating a line it is more effective to be able to borrow design elements from one CAD jewelry design and bring them straight into the next design.

Are you ready to begin! Simply click here to contact us

I will make sure you will be completely satisfied with your 3-D CAD jewelry design file or custom designed finished jewelry.